Home>Product Information>Metal-Bonded Wheel Forming Machine

Metal-Bonded Wheel

Forming Machine EDT300

While metal bonded wheels are highly productive, efficient and long-lasting for grinding cemented carbides, they are very difficult to correct and shape.

-

Superiority of Metal-Bonded Wheel

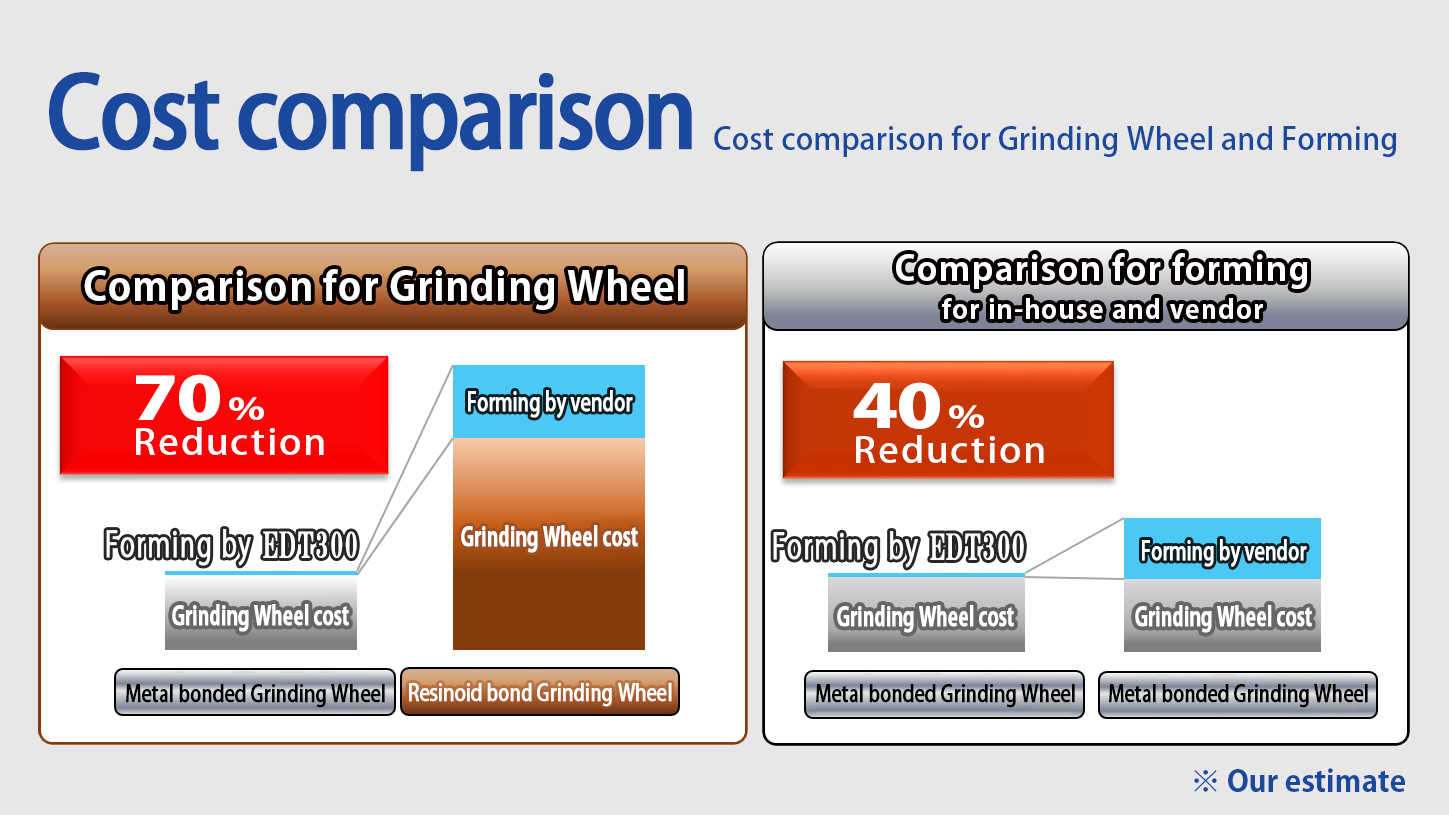

The lifespan of metal bonded wheels is about four times longer than that of resin bonded wheels, and the use of Metal-Bonded wheels reduces the cost by about 70% (compared to resin bonded wheels). On a cost conversion basis, the use of metal bonded wheels reduces the cost by about 70% (compared to resin bonded wheels). That is why it is easy to modify and mold the Metal-Bonded wheel in-house.

-

Electro Dischage Technology and Wire Electrode

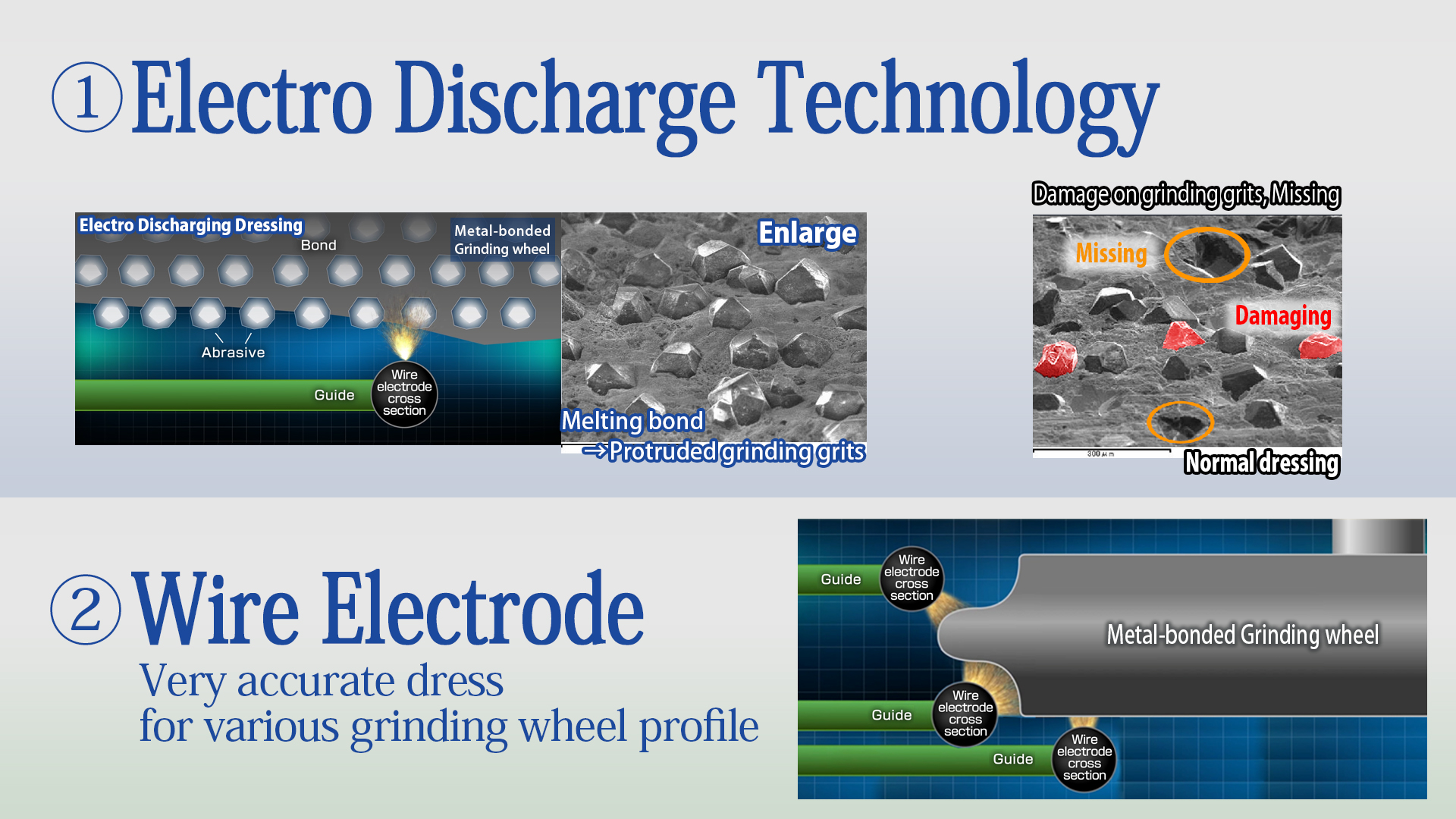

(1) Bond of Metal-bonded wheel is melted and removed by electro-discharge technology→Restores good sharpness without damaging the wheel.

(2) Highy accurate contour formation even with various wheel shapes by using wire electrodes. -

Specification

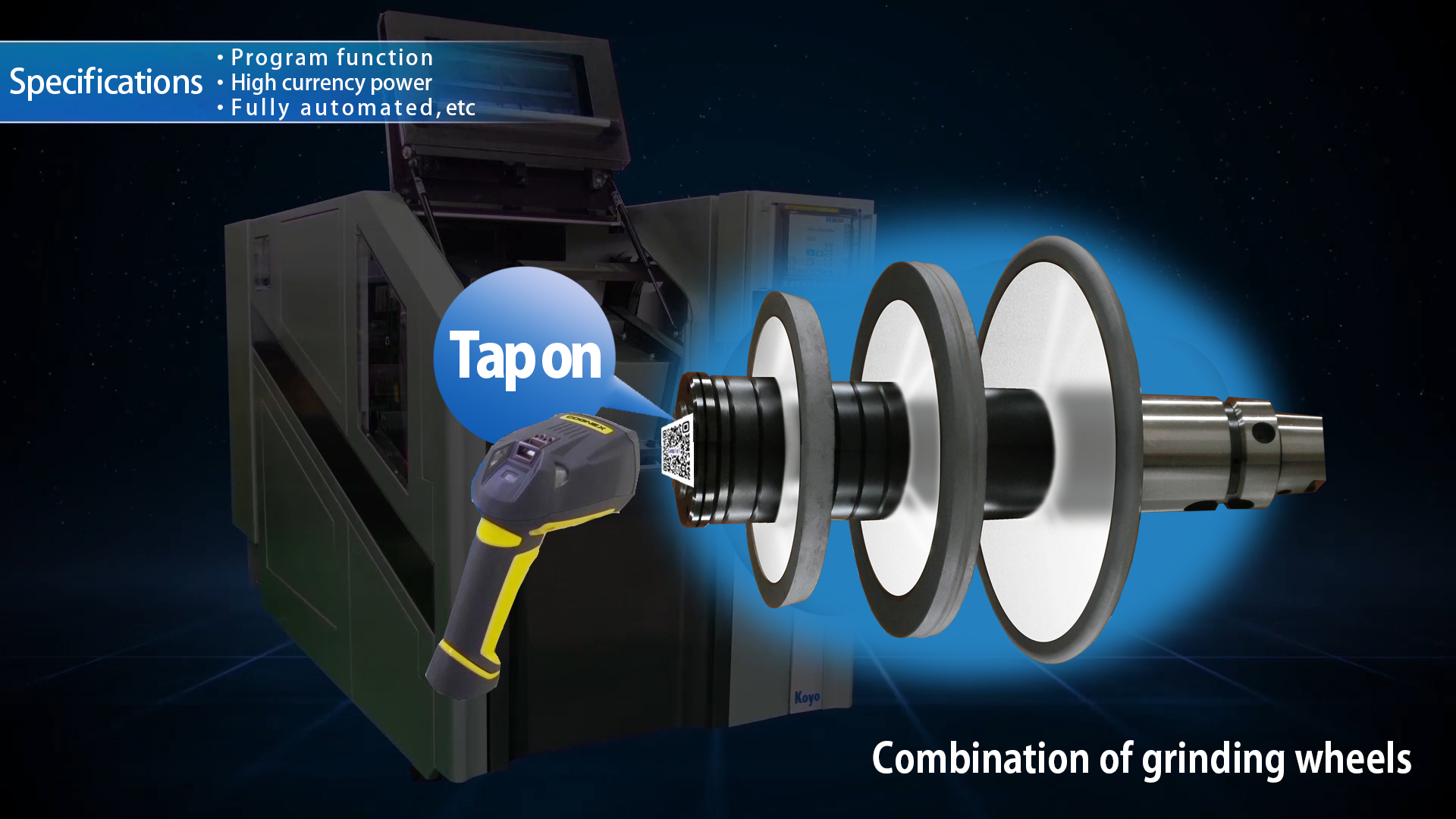

Install the combination wheels on the EDT300.Call the dress program with 2D code

and automatic operation until dress is completed with the start button.

Dress history is also saved and managed.Space-saving machine. -

Metal-Bonded Wheel Forming Machine

EDT300Explanatory Video (full length)

Electoro Discharge Dress

JTEKT MACHINE SYSTEMS CORPORATION

JTEKT MACHINE SYSTEMS CORPORATION