Home>Product Information>Precision Mechanical Equipment>Spindle Units>Compact High Speed Spindles

-

Compact High Speed Spindles

3.1 Description

Machining is performed in a wide range of areas from automobile parts to wafers of semiconductors, increasingly improving accuracy and productivity. To meet such trends, KOYO has developed compact spindles to be especially applied to special machines for machining of semiconductors by setting the applied rotating speed from 5,000 to 40,000 min-1. These spindles are designed to have high accuracy and precision. The reduced size was achieved by developing exclusive built-in motors that allow the capability of machining with robot arms. We believe that the use of these spindles will offer you an extensive advantage when they are integrated with your specialized machines.

3.2 Features

- (1)The built-in motors are compact high frequency motors with high output and brushless DC motors that use permanent magnets (neodymium magnets) for rotors depending on models.

- (2)Spindles with a high frequency motor can be driven in general purpose inverters.

- (3)Spindles with a brushless DC motor are driven by exclusive drivers.

- (4)For the supports of the main axes, bearings whose inside specifications are designed to support higher speed by using ceramics for rolling elements are adopted (high-ability bearings made by JTEKT).

- (5)Stable machining is realized by structures that fully minimize vibration due to imbalance of the main axes.

- (6)In machining of semiconductors, fine powder of workpieces travels into the spindles and significantly reduces the life of the bearings.However, these spindle units have been designed to prevent fine powder and coolant from traveling into the bearings with a well engineered labyrinth on the front side of the spindle.

3.3 Examples of Manufacturing

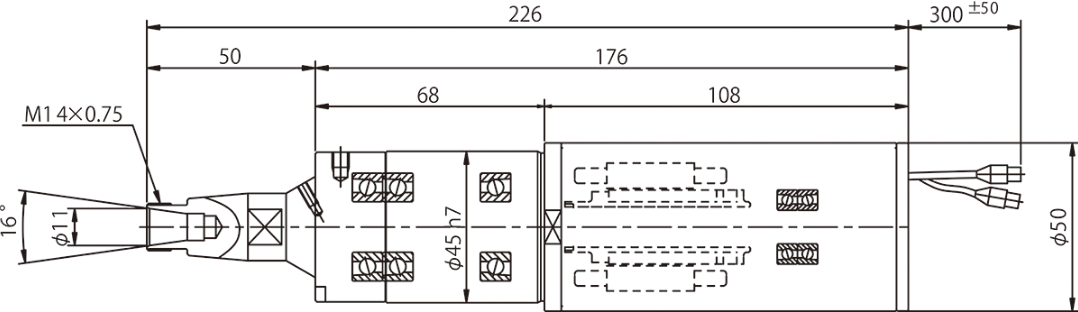

Maximum rotating speed:20,000min-1(IPM motor embedded)

■Structure

■Specification

Mounting direction

Vertical downward

Maximum rotating speed(min-1)

20,000

Tool interface

Collet

Tool coverage range(φ:mm)

0.5 to 7

Applied motor output(W)

Equivalent to 200

Cooling

Oil cooling

(tuning to room temperature)

Front bearing

Ceramic bearings (equivalent to 7002C)

Rear bearing

Ceramic bearings (equivalent to 7900C)

Lubrication

Grease

Rotation control

Exclusive driver

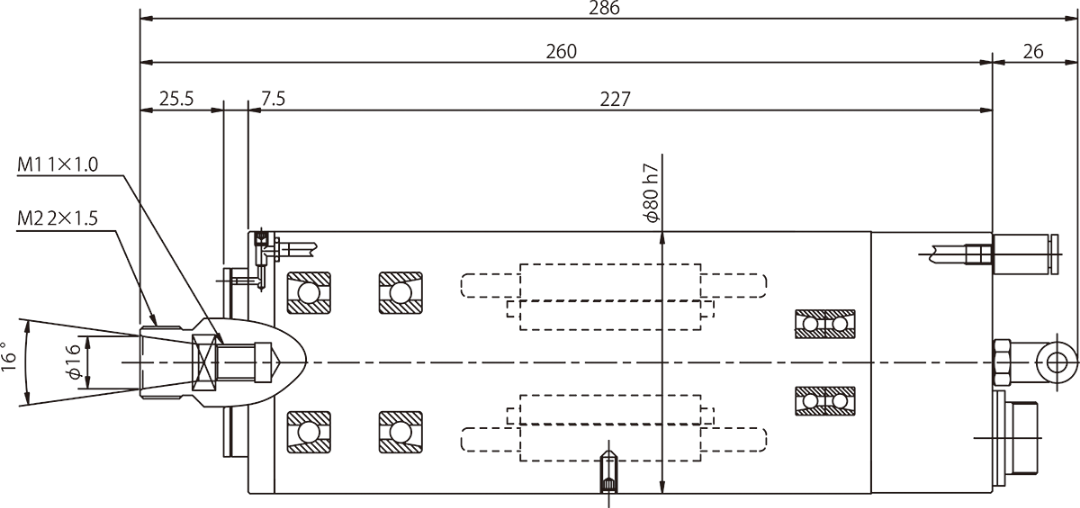

Maximum rotating speed:20,000min-1(induction motor embedded)

■Structure

■Specification

Mounting direction

Vertical downward

Maximum rotating speed(min-1)

20,000

Tool interface

Collet

Tool coverage range(φ:mm)

0.5 to 10

Applied motor output(W)

Equivalent to 1,000

Cooling

Oil cooling

(tuning to room temperature)

Front bearing

Ceramic bearings (equivalent to 7006C)

Rear bearing

Ceramic bearings (equivalent to 7002C)

Lubrication

Grease

Rotation control

General purpose inverter

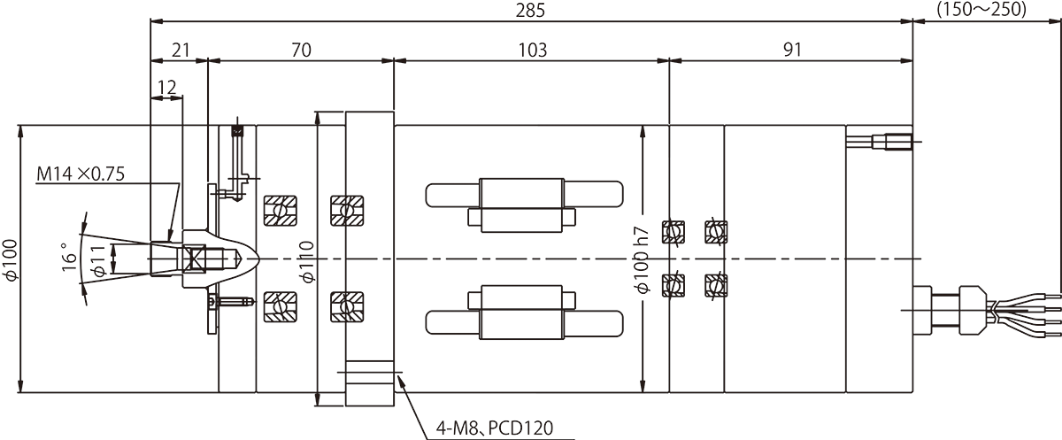

Maximum rotating speed:40,000min-1(high frequency motor embedded)

■Structure

■Specification

Mounting direction

Vertical downward

Maximum rotating speed(min-1)

40,000

Tool interface

Collet

Tool coverage range(φ:mm)

0.5 to 7

Applied motor outputt(W)

Equivalent to 1,000

Cooling

Oil cooling

(tuning to room temperature)

Front bearing

Ceramic bearings (equivalent to 7005C)

Rear bearing

Ceramic bearings (equivalent to 7001C)

Lubrication

Oil mist

Rotation control

General purpose high frequency inverter

-

Contact Us

If you have any questions about our products, please contact us.

JTEKT MACHINE SYSTEMS CORPORATION

JTEKT MACHINE SYSTEMS CORPORATION